You are here

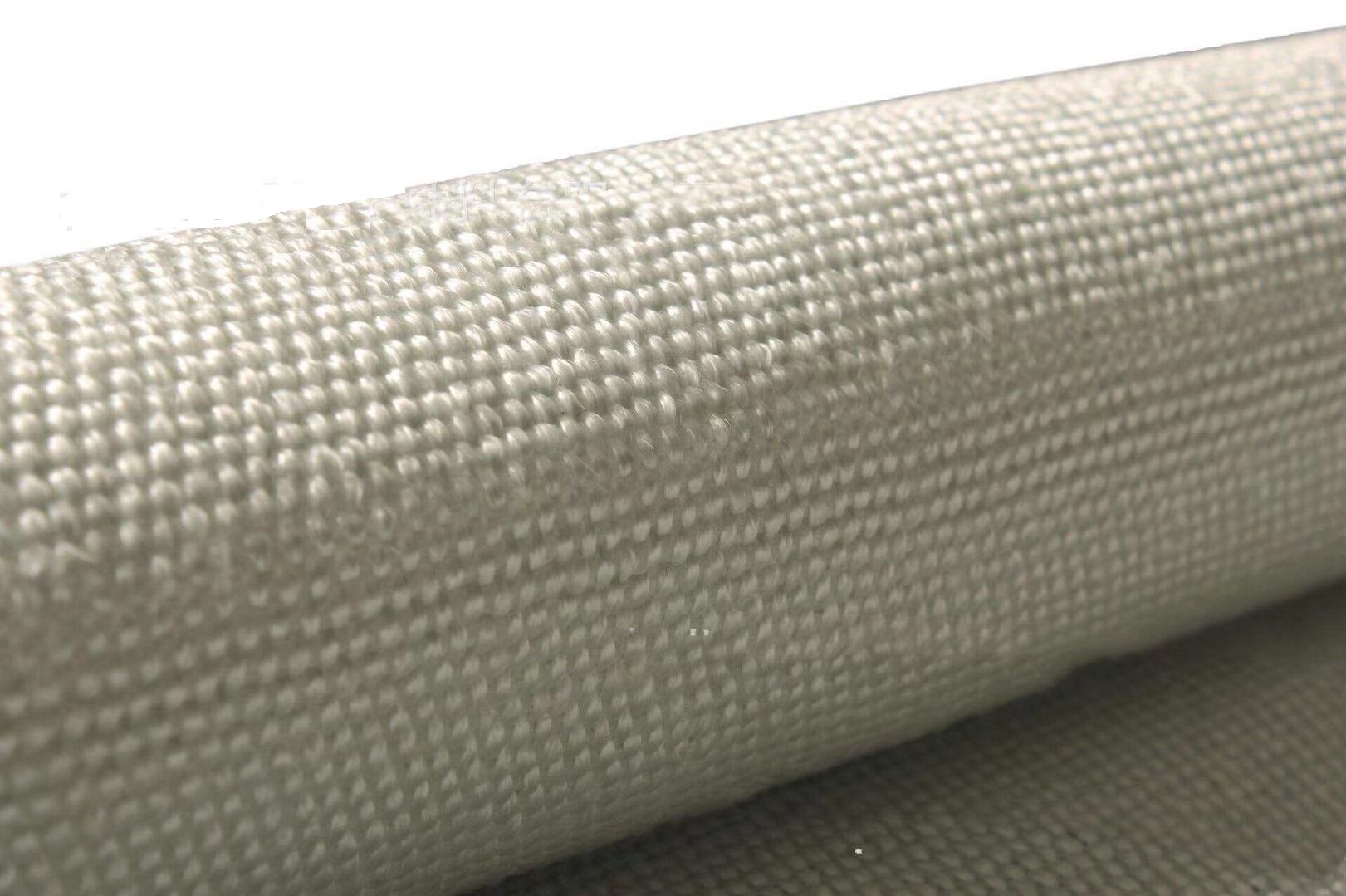

E-glass Fabrics Made of Textured Yarns

Fiberglass yarns consist of a defined number of E-Glass filaments of a certain nominal diameter, brought together to form a yarn. The structure of the yarn is fixed and protected by a size and a slight twist, generally in Z-direction.

These heat resistant fabrics withstand continuous operating temperatures up to 1000°F / 540°C and peak temperatures up to 1300°F / 700°C.

Because of its inherent bulk, texturized glass has unparalleled insulative properties. It is also incredibly well suited for additional processing applications such as braiding, weaving, and warping; the “texture” of the yarn provides an additional layer of strength to the end-product.

DANYTEX texturized fiberglass fabrics are available in a range of weights and constructions and with a variety of coatings. Options include:

| T63 | T63 is a starch/ silane /oil-based size system. Due to its special composition, all fiberglass yarns sized with T63 have a high tensile strength. The size abrasion is reduced to a minimum and the electric static build up is very low, even under demanding conditions. |

| T8 | Starch/ oil-based size system, being suitable for a large variety of textile processes. |

| T30 T32 5312 | Starch/ oil based size systems, especially designed for high speed air jet weaving machines and applications requiring good heat cleaning properties. |

| TD22 TD37 | Starch-free plastic size systems, containing silane bonding agents guaranteeing an excellent compatibility with different resin systems (epoxy,phenolic and unsatured polyester). |

| TD52 TD53 | These size systems are especially designed to provide excellent compatibility with PVC plastisols. |

| T18 | This size system is especially designed for texturizing, providing a very good protection for a mechanically demanding process and offering a high tensile strength. |

Applications Technologies Documents

Automobile Construction Electrical Industrial | Automobile Construction Electrical Industrial | Automobile Construction Electrical Industrial |